Scope

:- :-

A Proximity sensor can detect objects without

physical contact. A proximity sensor often emits an electromagnetic field or

beam and look for changes in the field. The object being sensed is often

referred to as the proximity sensor's target. Different proximity sensor

targets demand different sensors. For example, a capacitive or photoelectric

sensor might be suitable for a plastic target; an inductive proximity sensor

requires a metal target. This project mainly used in the in the proximity

sensor manufacturing unit.

Objective

The

objective of this project is to find out the maximum and the minimum sensing

point of the proximity sensor in order to determine the specifications of the

sensor.

Methodology

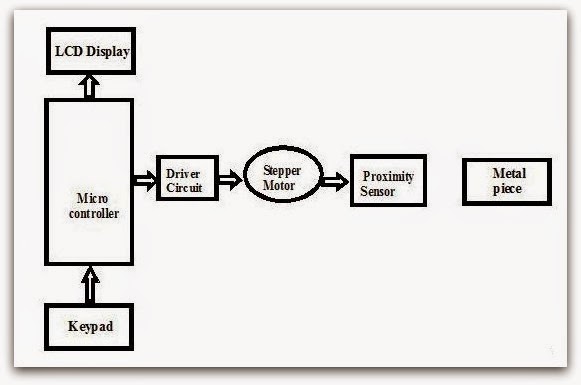

The Project is designed with the following blocks

such as

- Display

- Microcontroller

- Keypad

- Stepper driver circuit

- Stepper motor

- Proximity sensor

- Metal piece

In this project, the Keypad is used to set the

stepping angle of the stepper motor. A keypad consists of several push buttons and they

depend on our requirement. The stepping angle can be sent to the

microcontroller. A microcontroller

(or MCU) is a computer-on-a-chip used to control any electronic

device. The microcontroller is programmed already

according to our objective. The output signal from the microcontroller is passed to

the stepper driver circuit. The stepper driver circuit drives the stepper

motor. The stepper motor

converts electrical signal to mechanical movement. Stepper motors consist of a

permanent magnet rotating shaft, called the rotor, and electromagnets on the

stationary portion that surrounds the motor, called the stator. The rotation of

the stepper motor depends on the step angle. The stepper motor is connected to

the proximity sensor.Infront of the proximity sensor the metal piece is placed.

For a particular stepping angle, minimum length of sensing of the proximity

sensor is measured. Similarly for a particular stepping angle, maximum length

of sensing of the proximity sensor is measured. The minimum and the maximum

length are displayed on the LCD Display.

Advantages

- Accuracy in measurement can be achieved

- Speedy process

- Reliable

- Cheap in cost

- Low power consumption

Applications

The proximity calibration unit can be used in

detection of the E-ring insertion, checking of part ID affixed to pallet,

Determination of transistor placement, confirmation of seating of piston to be

drilled.

0 comments :

Post a Comment